20 Years Strong

The Secret to the Chet Holifield Federal Building’s Resilient Roof

by Steven C. Wadding RRC, RRO, CDT, Corporate Projects Manager, Polyglass USA

As a symbol of architectural excellence and engineering prowess, the Chet Holifield Federal Building continues to defy the elements two decades after its renovation. For those who have been familiar with Architectural West magazine since 2004, you may recall the March/April cover story featuring a stepped-pyramid building in Laguna Niguel, California, the Chet Holifield Federal Building. Originally built in 1970 for Rockwell International, the design embodies the futuristic vision of renowned architect William L. Pereira. A few years later, this architectural gem became a prized property of the General Services Administration (GSA).

In 2003, this now-historic site underwent significant renovation, including a new roof for most of the complex, spanning 480,000 sq.ft. CRC Consulting Group from Bakersfield, California, collaborated closely with Western Roofing Services, which is now a part of Tecta America, who were tasked with the challenging job of replacing this massive roof. Due to the sensitive operations housed within, such as the IRS and National Archives, the project came with strict guidelines: no interruptions, no fumes, and minimal noise, demanding meticulous planning and execution.

Western Roofing, having used Polyglass®’ self-adhered (SA) membrane products, quickly engaged Polyglass USA, Inc. in discussions to find the best way to meet the GSA’s stringent requirements. The solution was clear: Polyglass’ polymer-modified low-slope self-adhesive membrane systems were ideal for such restrictions. Aside from the noise of removing the old membrane and foot traffic on the roof deck, the process was unobtrusive.

One significant challenge was the near-zero slope of the existing roof deck. The solution began with a clean deck and the installation of a tapered polyisocyanurate system, bonded with low-rise foam adhesive, eliminating the need for thousands of fasteners. A cover board, also bonded with foam, provided a solid surface for the roofing system. Polyglass’ two-layer system, consisting of Elastoflex SA V base/interply membrane and Polyflex® SA P APP mineral cap sheet in a buff-colored finish, flawlessly adhered to the surface. This ensured the building remained dry and secure throughout the process.

Western Roofing worked diligently to install the Polyglass SA system while protecting tenants and the building’s valuable contents. The collaboration between Western Roofing, CRC Consulting, and Polyglass Technical Services was a resounding success, delivering a watertight roofing system on time, within budget, and in full compliance with GSA’s requirements. The absence of tenant complaints throughout such a complex project was, in itself, a remarkable achievement. Polyglass proudly issued a 20-year roofing system warranty upon completion.

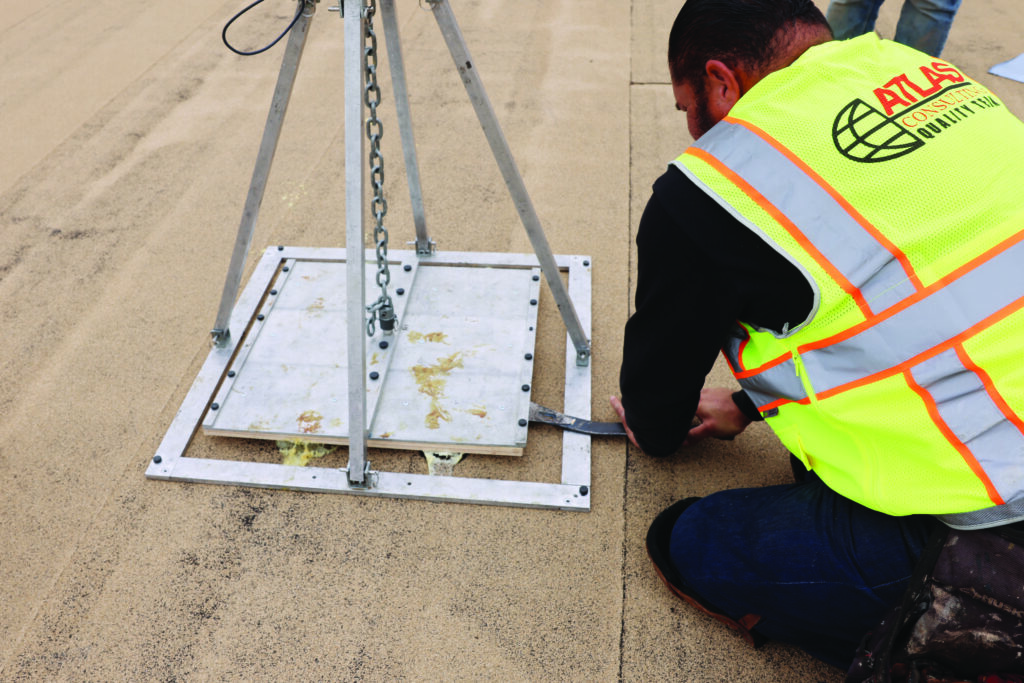

Fast forward 20 years, rumors circulated in 2022 that the GSA might sell the property, as many of its federal tenants had relocated. Despite not hearing any complaints or receiving warranty claims, Polyglass’ Technical Services team initiated discussions with the building’s representatives to walk the roofs and document their condition. Polyglass enlisted Gary Weaver of Atlas Consulting to assist in communication and review. Given Weaver’s past experience with the building and his skepticism of self-adhesive membranes, his involvement proved crucial. “My experience with modified bitumen since the 1970s was great, but several of the self-adhered membranes I experienced in the early 2000s and up until this survey all seemed extremely problematic,” said Weaver. This skepticism made his positive assessment of the Polyglass SA membrane even more significant.

Upon visiting the site, the team discovered that large sections of the roof had experienced two decades of foot traffic, including workers installing an extensive rooftop solar panel system. The roof’s remarkable resilience, even after such extensive use, is a testament to the quality of the Polyglass SA membranes. “The Polyglass SA membranes used on the Chet Holifield Federal Building have performed so exceptionally,” said Weaver.

To further assess the roof’s performance, Polyglass obtained permission to have Atlas Consulting perform a full qualitative assessment and quantitative testing of the roof. This included bonded roof tests, moisture detection with infrared thermography and visual observations of the multiple roof areas. Furthermore, test cuts were taken from various parts of the roof and sent to Polyglass’ R&D labs in Deerfield Beach, Florida, for an analysis of seam integrity and close inspection of the various layers of 20-year waterproofing material using a scanning electron microscope.

The results were conclusive: the roof system continued to exceed performance expectations after 20 years of service, with Weaver predicting a remaining life of another 30 to 35 years.

Coinciding with this monumental project, Polyglass had developed and introduced Adeso® self-adhered technology, revolutionizing the application of polymer-modified bituminous membranes. This innovative technology eliminates the need for hot asphalt or mechanical fasteners, offering a faster, cleaner, and more user-friendly installation process.

The success of the Chet Holifield Federal Building project serves as a powerful example of the durability and performance of Adeso technology. After 20 years of exposure to the elements and significant foot traffic, the roof system continues to function flawlessly. This longevity underscores Polyglass’ commitment to providing innovative solutions that meet the evolving needs of the roofing industry.

For those who remain hesitant about polymer-modified self-adhesive membranes, this project serves as a testament to their longevity. After over 20 years, Polyglass’ revolutionary membrane system continues to stand the test of time, proving it is on par with, if not superior to, other commercial membrane systems.